Dubai, UAE, 2012: When Al Liali jewelry invited me to a factory visit at Dubai Commodities Centre you can imagine how thrilled I was. My experience with the Al Liali brand and staff have been very pleasant since my visit to view their handcrafted line of jewelry for Mother’s Day in May 2012.

The factory trip helped me and the other bloggers present namely Isaac Ode and Shweta Dembla (Dubai in a Frame) understand the long tedious process that goes on behind the making of any kind of precious metal jewelry. Even a simple ring demands great attention to detail!

I am familiar with the lost wax casting process simply because I became acquainted with it while I was working with precious metal clay. I wanted to find a way that I could duplicate a design – the first piece being done by me – so as to avoid the long process of recreating a second pieces which would be a twin.

Lost wax casting has a french name called Cire Perdue. It is a technique used for precious metals like silver and gold. As well as bronze and brass. It is believed that the modern lost wax method is quite similar to what was used in the ancient Egypt and South American tribes.

Here is an idea of what goes on in a typical lost wax casting process. If you decide to make a line of jewellry or accessories in one go instead of having to carve each one of them, lost wax casting is the way.

– Once you have created your design you make a metal or resin model.

– A rubber mould is then made from this model. Wax is used to generate multiple copies of this mould which are then attached to a rubber base and looks like branches of a tree. It is called Spruce Sadly I was so engrossed in the process I forgot to take a picture of this tree but I do have a stand alone wax model. This is how it will look like in gold once it’s gone through the whole process.

– The trees is put in a metal flask which is then layered by investment (similar to plaster of paris). Then it is heated in an oven after hardening and the max melts away – thats why the term lost wax – and you are now left with a hollow mould.

After the Investment is used and the metal flasks placed in the oven, the wax melts. Now it’s waiting for centrifugation.

– Then the alchemy happens wherein the gold enters the mould and takes the form of the original design. The methods used could be either vacuum casting or centrifugal casting.

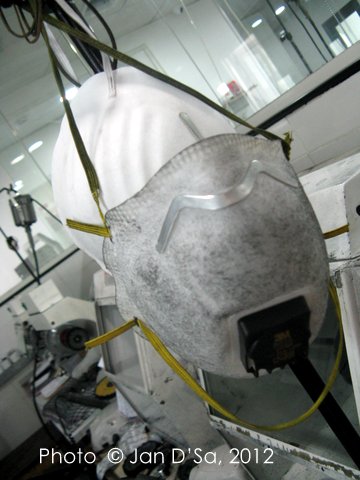

– Time to break the plaster and show the cooled gold casting which is still not shiny. The shininess is given in the burnishing room – a stand alone room that reminds me of one of the chemistry labs that I used to perform chemical experiments as a degree student. One has to wear a mask in the burnishing room to prevent one from inhaling any micro-particles floating around. There are two types of burnishing systems used: barrel tumbling system or a vibratory bowl system.

Burnishing time. These are the rings that have gone through the tortorous process. They have been dismounted from the tree that was created in the wax process. You can see that they lack the sheen. That’s what burnishing with do.

Hand burnishing takes a long time and therefore machine burnishing is an easy way out. I, myself, when I have created silver pieces of jewelry using the Precious Metal Clay technique, found burnishing to be the hardest part. Some silver artisans on a small case basis will usually buy a small tumbler to help in the process especially if they focus on making silver pieces.

This is the close up of the mould that I was carrying. Seems that there are four rings in the mould waiting to be mounted with some very expensive gemstones!

At the Al Liali factory, I got to see the smiths engrossed in the hand finishing. I believe many of them studied precious metal smithing from the time they were tiny tots. I forgot to take a peep in the microscope to appreciate the eye intensive work that the smiths had to do in order to ensure they got that precious ruby sitting exactingly within the shimmer of diamonds on the ring.  So different from my own laboratory days where when I stared into the microscope I saw a dissected insect or a plant laying bare.

Out of focus. I deliberately left the ring out of focus, to capture that porous tool that held the ring so that the smith can work with great ease.

I know that silver artisans do similar types of work on a smaller scale but to see something done on an industrial level actually helps people understand the process and how important it is to ensure high quality of craftsmanship. As I walked out of the factory, the summer hear bore down on me, but the excitement of being shown around such a factory was a dream come true. Thank you Al Liali for making my dream come true.